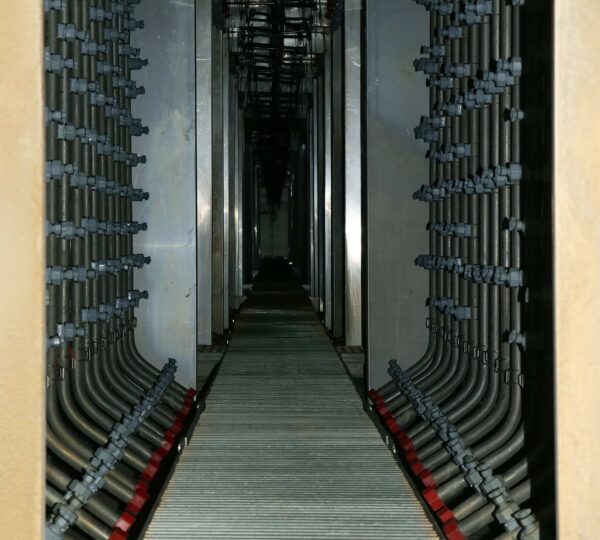

Flame Pre-Treatment System

Flame pre-treatment is a surface preparation technique used in the coating industry, where a controlled flame is applied to the surface of a substrate (typically plastics or composites) to improve its adhesion properties. The heat from the flame oxidizes the surface and increases its surface energy, making it more receptive to coatings, adhesives, or inks. This method is commonly used for materials with low surface energy, such as polyethylene, polypropylene, or other plastics, which are traditionally challenging to coat without pre-treatment.

Flame pre-treatment involves exposing the surface of a substrate to a controlled, high-temperature flame. The flame alters the chemical structure of the surface, increasing its wettability and surface energy, making it more suitable for coating or adhesion. It is particularly effective for non-metallic surfaces like plastics.

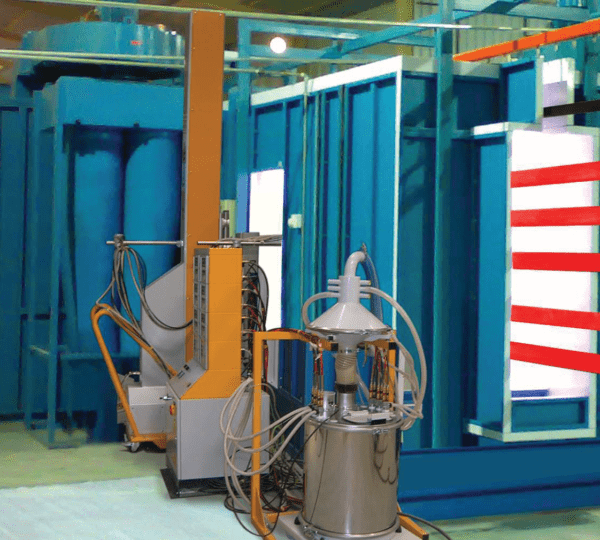

In the establishing year 1998, TECHExpert Engineering Pvt Ltd embarked on a journey in the manufacturing industry for Surface Coating Plants and Equipment. In less than two decades, we have become the leading genus in Designing, Manufacturing, Supplying and Exporting a wide range of Pre-Treatment Plant, Flame Pre-Treatment, Pre-Treatment Manufacturer, Powder Coating Plant, Paint Booth Manufacturer, Industrial Oven Manufacturer, Curing Oven Manufacturer, Material Handling Equipment, Conveyor Suppliers, Industrial Ducting Suppliers, and Shot Blasting System.

Benefits of Flame Pre-Treatment System

- The oxidation of the surface during flame treatment increases its surface energy, allowing coatings, paints, and adhesives to bond more effectively to the substrate.

- Flame treatment is a quick process that can be easily integrated into production lines, allowing for continuous treatment of parts without significant delays.

- Since flame treatment relies on thermal energy, it eliminates the need for chemical solvents or wet treatments, reducing the environmental impact and operational costs associated with waste disposal.

Use of Flame Pre-Treatment System

- Flame pre-treatment is used to prepare plastic parts, such as bumpers and interior components, for painting or coating to ensure the paint adheres well and lasts longer.

- Commonly used for treating plastic packaging materials (e.g., bottles, containers) to improve adhesion for labeling, printing, or coating applications.

- Flame treatment is used on plastic casings and parts in electronics to ensure strong adhesion of coatings or decorative finishes, enhancing product durability and appearance.

TECHExpert Engineering Pvt Ltd, we have grown into offering end-to-end solutions in the field of Surface Coatings, beginning with Consultancy, Designing, Engineering, and Commissioning of tailor-made systems for powder coating, liquid painting, and Metal pre-treatment, on a turnkey basis, for a wide range of utilization necessities of finish coating for industrial and customer products.

Further, to attain maximum satisfaction of clients, we provide after sales service with the help of our trained and experienced engineers. Our vast industry experience and in-depth knowledge have helped us in acquiring huge base of clients not only in India but also in overseas countries like UAE, Bahrain, Qatar, Quwait, Africa, and Oman.