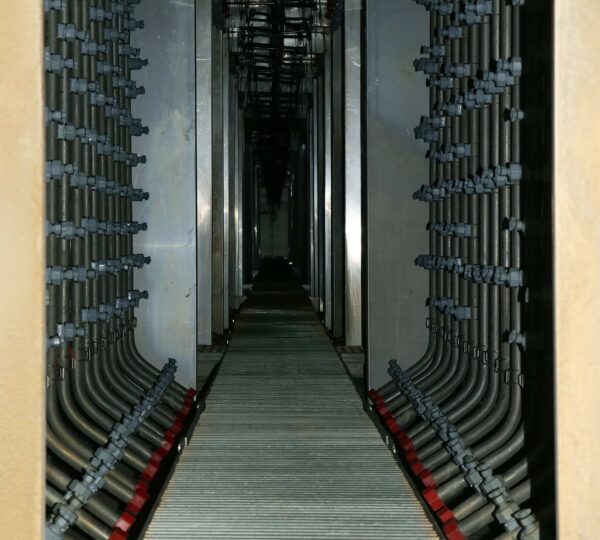

DIP/Immersion Pre-Treatment System

A dip/immersion cleaning system is a widely used pre-treatment method in the coating industry, where parts or materials are submerged in a series of chemical baths for cleaning and surface preparation. This system is effective for treating complex geometries, large components, or parts with cavities that may be difficult to clean using other methods like spraying. The immersion process ensures thorough cleaning and application of conversion coatings, making it ideal for industries such as automotive, aerospace, and heavy machinery.

In a dip/immersion cleaning system, parts are submerged in chemical baths that remove contaminants (e.g., oil, dirt, rust) and apply protective coatings. The process involves multiple stages, including cleaning, rinsing, surface activation, and conversion coating. It is ideal for handling large or intricately shaped parts.

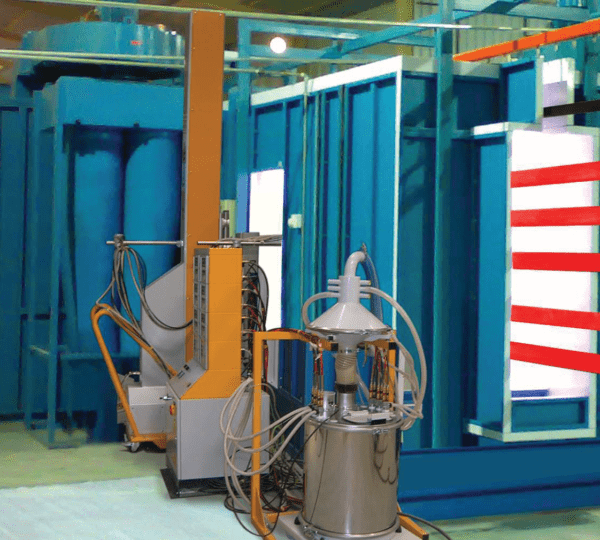

In the establishing year 1998, TECHExpert Engineering Pvt Ltd embarked on a journey in the manufacturing industry for Surface Coating Plants and Equipment. In less than two decades, we have become the leading genus in Designing, Manufacturing, Supplying and Exporting a wide range of Pre-Treatment Plant, DIP Pre-Treatment, Pre-Treatment Manufacturer, Powder Coating Plant, Paint Booth Manufacturer, Industrial Oven Manufacturer, Curing Oven Manufacturer, Material Handling Equipment, Conveyor Suppliers, Industrial Ducting Suppliers, and Shot Blasting System.

Benefits of Dip/Immersion Pre-Treatment System

- The immersion process ensures that every part of the surface, including hard-to-reach areas like cavities, blind holes, or complex shapes, is fully cleaned and treated.

- Immersion systems provide even distribution of conversion coatings, ensuring a consistent layer of protection on all surfaces, improving coating adhesion and performance.

- The uniform application of conversion coatings such as phosphates or chromates provides excellent corrosion resistance, extending the lifespan of metal components, particularly in harsh environments.

Use of Dip/Immersion Pre-Treatment System

- Used for cleaning and applying corrosion-resistant coatings on metal components like car bodies, engine parts, and frames before painting, ensuring longevity and protection from rust.

- Large metal parts in construction or agricultural equipment are pre-treated using immersion cleaning to provide superior protection against harsh environmental conditions and heavy wear.

- Aircraft parts, especially those with complex geometries, are submerged in chemical baths to remove contaminants and enhance the adhesion of protective coatings, ensuring resistance to extreme conditions.

TECHExpert Engineering Pvt Ltd, we have grown into offering end-to-end solutions in the field of Surface Coatings, beginning with Consultancy, Designing, Engineering, and Commissioning of tailor-made systems for powder coating, liquid painting, and Metal pre-treatment, on a turnkey basis, for a wide range of utilization necessities of finish coating for industrial and customer products.

Further, to attain maximum satisfaction of clients, we provide after sales service with the help of our trained and experienced engineers. Our vast industry experience and in-depth knowledge have helped us in acquiring huge base of clients not only in India but also in overseas countries like UAE, Bahrain, Qatar, Quwait, Africa, and Oman.